technology

TECHNOLOGY

Our company specializes in metal presses, specializing in precision deep drawing using transfer press machines and precision cutting using NC automatic lathes. We produce precision deep drawing/precision cutting products such as temperature sensor parts, writing instrument parts (mechanical pencils, ballpoint pens, markers), surge components, and mobile phone parts, earning high praise from customers both in Japan and overseas.

transfer press machines, in particular, excel in mass production, enabling mass production at low cost and high quality. Our company operates under a consistent management system, from mold design to manufacturing and mass production of finished products, and we will continue to strive for zero defects under our motto of "quality first."

We have experience manufacturing a variety of materials and shapes in addition to the products listed here. We look forward to hearing from you.

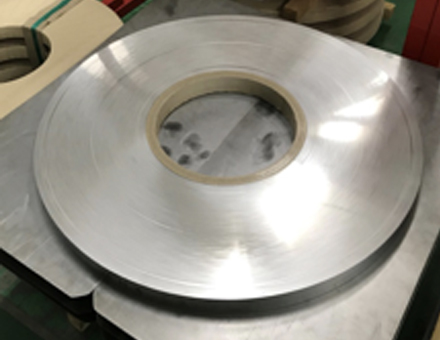

Press processing

Our company uses transfer presses to carry out batch production from material input to completion. A transfer press is a press machine that arranges molds for multiple processes in the order of their processes and is equipped with a transfer mechanism (transfer mechanism) to transport them to the next process. The introduction of transfer presses allows us to achieve a low-cost, continuous, high-quality production system. We have also achieved deep drawing of stainless steel, a material known for its high processing difficulty. For pen tip parts, we are capable of precision deep drawing with inner diameters of φ1mm or less, and have a proven track record of producing 200 million units per year. We design and manufacture the molds required for our presses in-house, allowing us to maintain a consistent management system right up to mass production. Our in-house molds are manufactured to the micron level of precision, and can process product sizes ranging from φ1.0 to 6.0mm and lengths of approximately 30mm.

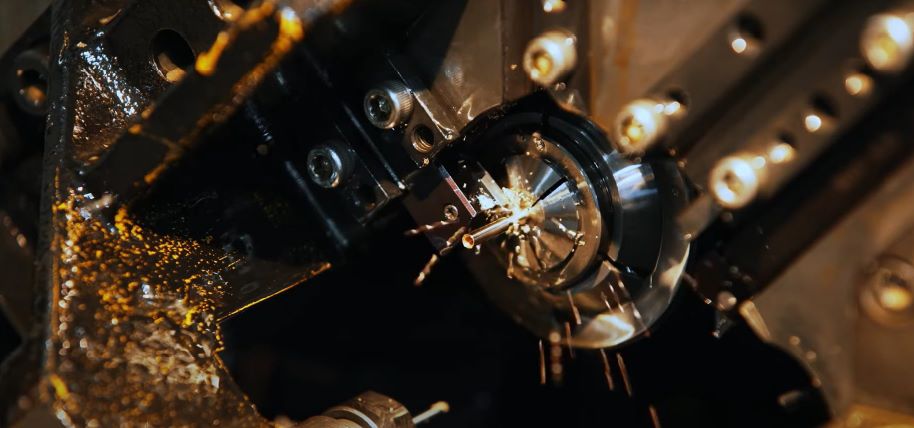

Cutting processing

Cutting is the process of using a special blade to remove material from a rotating object. It's similar to peeling an apple. NC automatic lathes, machines that perform automatic machining using numerical control, are used to cut bar stock into the desired shape. Special processing such as drilling small holes less than φ0.3 mm, slits, and knurling is also possible. Our specialty is processing sizes ranging from φ0.5 to φ8.0, and we can process up to φ16. In particular, we are able to produce over 3 million mechanical pencil chucks per month. Utilizing 134 automatic lathes, we are able to achieve mass production at low cost.

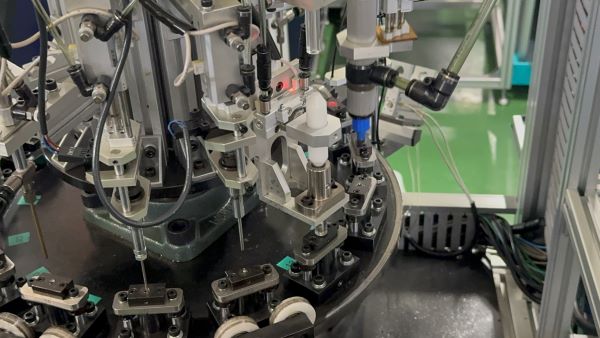

Secondary processing

Secondary processing is the further processing of products after pressing and cutting. For example, slitting the sides of the chuck, opening the chuck to open and close it, and caulking the fineliner (using pressure to deform the material and join the tip and part). We also automate the assembly of pencil mechanisms as an assembly process. We design, develop, and produce the machines that perform secondary processing in-house. By consistently carrying out processes from production to secondary processing, we are able to process a wide variety of shapes.